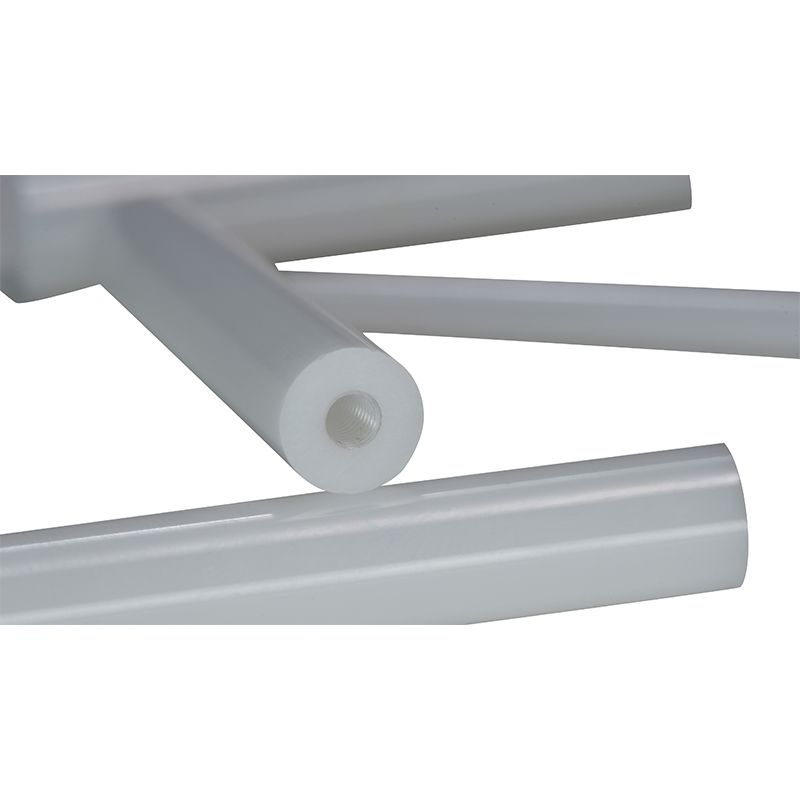

Threaded Ceramic Components

Threaded ceramic components combine the excellent properties of advanced ceramics with precise threading to enable reliable integration in mechanical assemblies. These parts are ideal for environments requiring high wear resistance, corrosion resistance, and thermal stability, where traditional metal fasteners may fail. Commonly used in semiconductor equipment, chemical systems, and high-temperature applications.

- High precision threads for reliable fitting

- Corrosion and chemical resistance

- High hardness and wear resistance

- Thermal shock and heat resistance

- Custom threading options available

Threaded Ceramic Components

Threaded ceramic components are specialized parts made from ceramic materials that feature threaded features, allowing them to be used in applications where a secure, high-performance connection is required. These components are used in a wide range of industries, including electronics, aerospace, automotive, medical devices, and more. The primary benefit of using ceramics for threaded components is their superior properties such as high hardness, wear resistance, heat tolerance, and electrical insulation, which make them ideal for specific, demanding environments.

Technical Specifications

| Parameter | Typical Range |

| Length Range | ≤300mm |

| Outer Diameter | ≤150mm |

| Surface Roughness | Ra0.02-Ra0.2 |

| Minimum Wall Thickness | 0.1mm |

| Roundness | 0.002mm |

| Concentricity | 0.002mm |

| Straightness | 0.004mm |

| Perpendicularity | 0.005mm |

Please refer to our Processing Capability Table for the full range of processing capability.

Advantages of Threaded Ceramic Components

- High Mechanical Strength: As a result of their robust composition, these components withstand tension and compression in threaded assemblies.

- Thermal and Chemical Resistance: Consequently, they perform reliably under extreme temperatures and in corrosive environments.

- Wear and Abrasion Resistance: This ensures long-lasting performance in dynamic systems and high-friction interfaces.

- Electrical Insulation: Therefore, they are ideal for applications requiring high-voltage isolation or dielectric properties.

- Precision Machining: Thanks to advanced manufacturing techniques, they can be produced with tight tolerances for secure and accurate thread engagement.

- Non-Magnetic and Non-Conductive: As such, they are well-suited for sensitive electronic, RF, or MRI-compatible applications.

Applications of Threaded Ceramic Components

- Vacuum and High-Temperature Assemblies: In these environments, they serve as secure fasteners without deforming under heat or pressure.

- Electrical Insulation Systems: Accordingly, they are used as insulating mounts or standoffs in high-voltage or electronic equipment.

- Medical Devices: Because of their biocompatibility and sterilization tolerance, they are suitable for medical imaging and surgical assemblies.

- Semiconductor and Laboratory Equipment: As a result of their chemical resistance and purity, they are employed in cleanroom and analytical systems.

- Optical and Laser Equipment: Thus, they offer stable, non-reactive mounting solutions for precision optics and photonic instruments.

- Aerospace and Defense: Given their lightweight, heat resistance, and non-conductivity, they are integrated into advanced engineering applications.

Enquire Now

- Welcome to contact us for more product information and quotes!

- Support customization according to drawings, quick response, short delivery guarantee!

- Consult Now

English

English 中文

中文