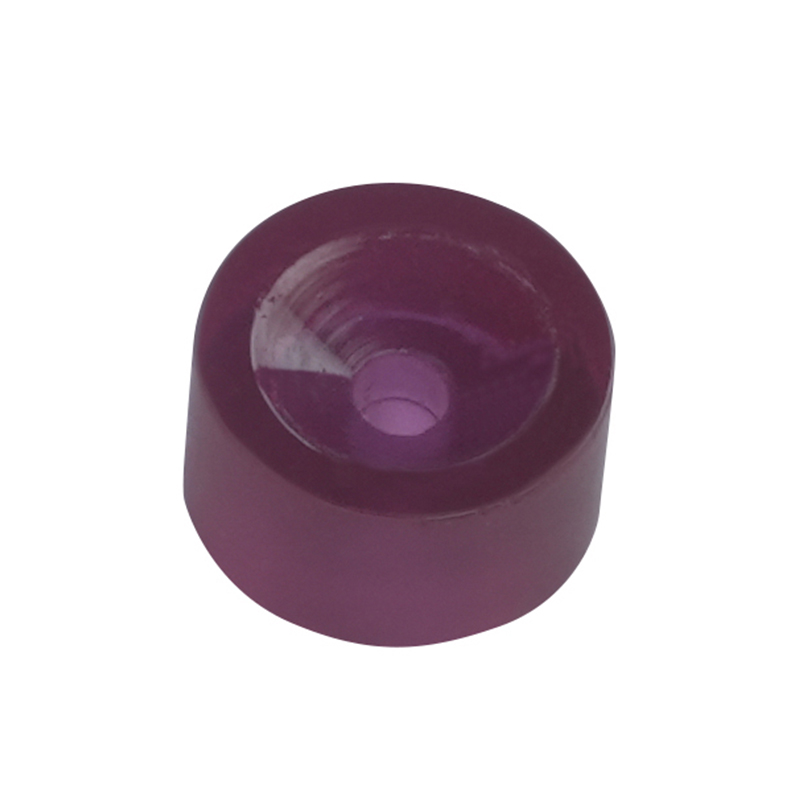

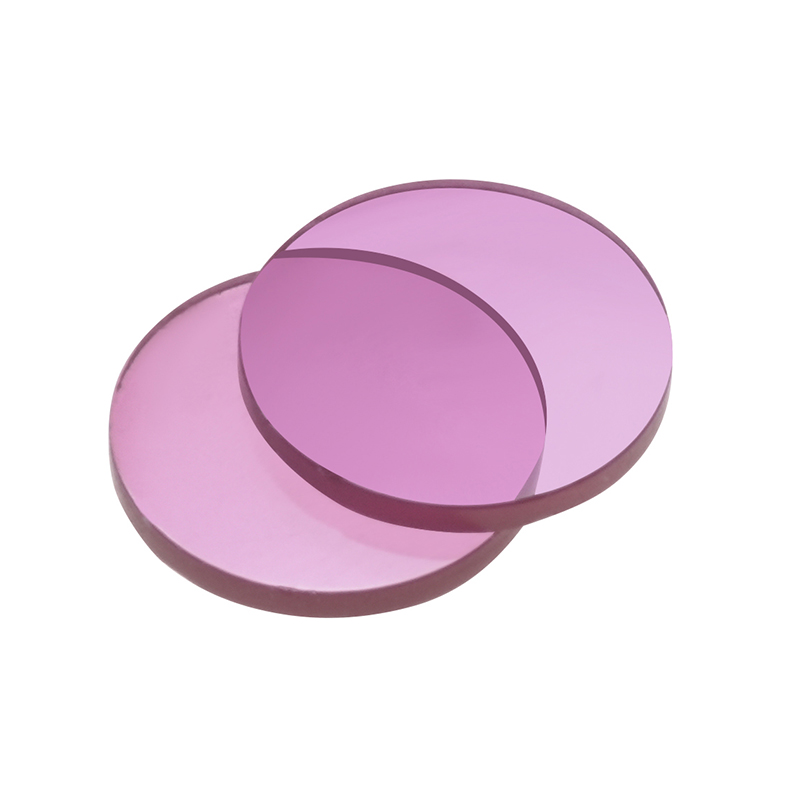

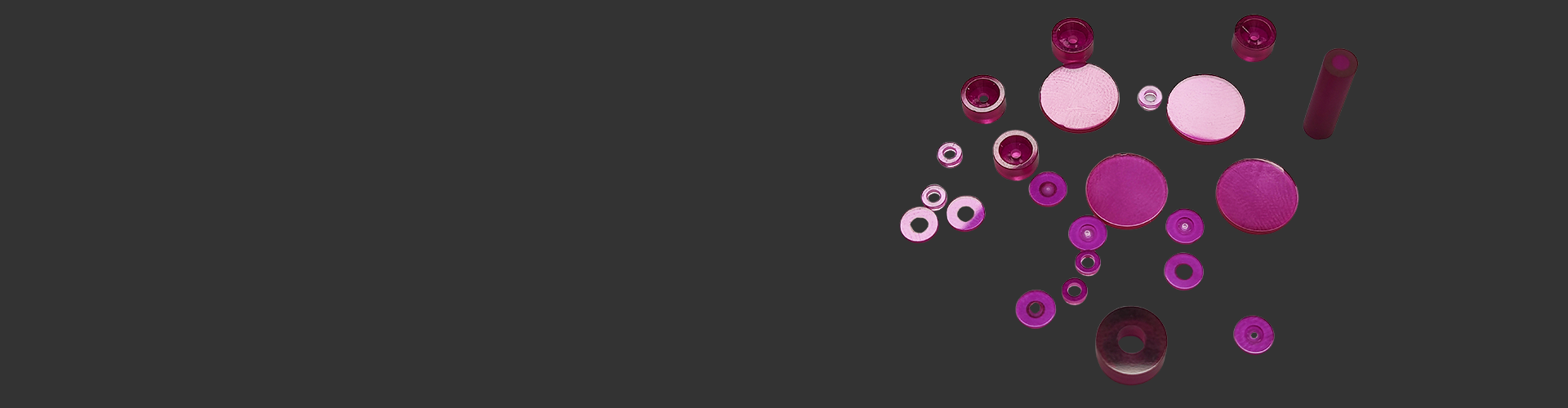

Sapphire Ruby Components

Using high-quality single-crystal alumina material, we provide ruby and sapphire series products with excellent wear resistance, corrosion resistance and high light transmission, which are suitable for precision measuring instruments, optical sensors and high-end industrial equipment and other fields.

1. 20+ years of ceramic manufacturing experience

2. Factory-direct supply with guaranteed quality

3. Custom production available

4. Made from industrial ruby and sapphire

5. Widely used in medical, aerospace, machining and precision instruments

PRODUCTS

Sapphire and ruby components are engineered from single-crystal aluminum oxide (Al₂O₃), making them among the most durable and versatile materials used in advanced engineering. These materials are highly valued for their exceptional hardness, thermal stability, chemical resistance, and optical properties.

While sapphire and ruby share the same base crystal structure, they differ in coloration and some optical behaviors due to trace elements (chromium in ruby). These differences are leveraged across industries to serve specific functional purposes. From aerospace optics and medical imaging to precision fluidics and semiconductor components, sapphire and ruby parts are integral to applications where ordinary materials fail.

What Are Sapphire and Ruby Components?

Both sapphire (colorless) and ruby (red) are crystalline forms of corundum. The extreme hardness (Mohs 9), second only to diamond, makes them ideal for use in harsh environments requiring resistance to wear, corrosion, heat, and pressure.

Ruby contains trace amounts of chromium, giving it a distinct red color and slight differences in optical properties. However, mechanically, ruby and sapphire are nearly identical — enabling interchangeable usage in many structural and mechanical applications.

Key Properties

| Property | Sapphire | Ruby |

| Chemical Formula | Al₂O₃ | Al₂O₃ (with Cr) |

| Hardness | 9 Mohs | 9 Mohs |

| Color | Transparent/Clear | Red |

| Optical Transmission | UV to IR (150nm–5500nm) | Visible Red |

| Melting Point | 2050°C | 2050°C |

| Thermal Conductivity | High | High |

| Corrosion Resistance | Excellent | Excellent |

Industries We Serve

-

Aerospace & Defense – For high-velocity, high-pressure optical systems and infrared domes.

-

Medical & Life Sciences – In endoscopy, diagnostics, and laser therapy.

-

Industrial Automation – For bearings, guides, and high-pressure nozzles.

-

Semiconductor & Electronics – For insulating parts, plasma-resistant tubes, and wafer processing tools.

Why Choose Us?

1. Engineering Expertise

With decades of experience, we provide not just materials — but full engineering support, from concept to completion.

2. Unmatched Tolerances

Our parts are machined to tolerances as tight as ±1 micron, ensuring perfect fits for even the most sensitive applications.

3. Rapid Turnaround

In-house production allows for faster prototyping and delivery, even on complex or custom components.

4. Surface Finishing Excellence

We offer a range of surface finishes, including:

-

Optical polish (<5Å RMS)

-

Frosted or matte

-

Laser-engraved marking for traceability

5. Consistent Quality

Our components go through rigorous inspection, including interferometry, profilometry, and dimensional analysis, guaranteeing reliable performance batch after batch.

Sapphire and ruby components are essential for modern systems that demand reliability, precision, and endurance under extreme conditions. Whether you require high-performance optical windows, wear-resistant ruby orifices, or custom sapphire assemblies, our solutions are engineered to deliver.

At UPCERA, we don’t just supply parts — we provide performance, consistency, and customization that elevate your product's capabilities. Contact us today to discuss your application, request a quote, or collaborate on a custom component.

English

English 中文

中文