SC Type Ceramic Sleeve China: A Guide to Top Manufacturers

Finding a high-quality SC type ceramic sleeve in China is a critical task for any company in the fiber optics industry. These tiny components are the heart of the SC connector. Their precision directly controls network performance. China dominates the global market for these parts. This means you have many options, but it also means finding a true, high-quality manufacturer requires a clear strategy.

This guide is that strategy. We will explore what an SC sleeve is and why Chinese manufacturing is so advanced. We will detail the manufacturing process, from raw powder to the finished part. Most importantly, we will provide a step-by-step framework for vetting suppliers. This will help you sort through trading companies and find a long-term manufacturing partner.

What Exactly is an SC Type Ceramic Sleeve?

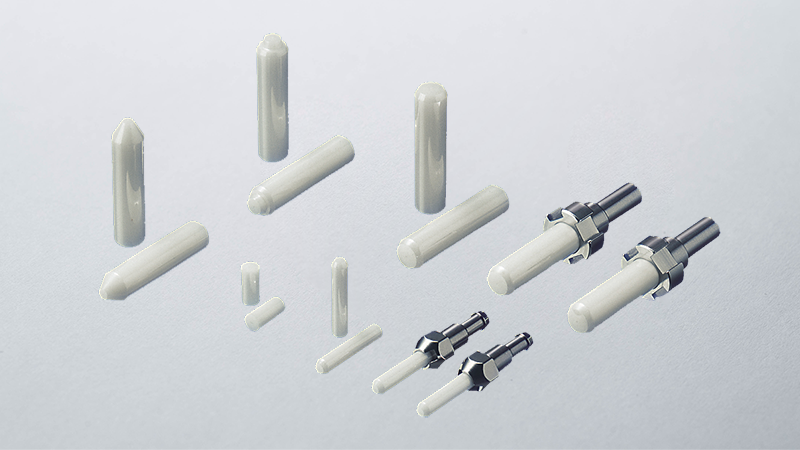

An SC type ceramic sleeve is a precision-engineered alignment component. It is the central part of an SC (Subscriber Connector) fiber optic connector. Its only job is to align the cores of two fiber optic ferrules with microscopic accuracy.

What is the function of an SC ceramic sleeve?

The primary function of an SC type ceramic sleeve is to align two fiber optic ferrules inside a connector. It is a small, split tube, usually made of zirconia. This precise alignment ensures that light passes from one fiber to the other with minimal signal loss (low insertion loss).

The sleeve itself is a small cylinder with a precise inner diameter. It is almost always "split," meaning it has a thin slot running down its length. This split allows the sleeve to act like a spring. It compresses slightly when the ferrules are inserted. This provides a firm, consistent grip that holds the fiber cores in perfect alignment.

The Material: Why Zirconia?

These sleeves are not made from the same ceramic as a coffee mug. The standard material is Zirconia (Zirconium Oxide). This advanced ceramic is chosen for several key reasons:

- High Fracture Toughness: Zirconia is very resistant to cracking. This is vital because the sleeve is split and must handle the stress of ferrule insertion thousands of times.

- Fine Grain Structure: Zirconia can be polished to an extremely smooth surface. This prevents the end of the fiber ferrule from being scratched or damaged.

- Similar Thermal Expansion: Its thermal expansion rate is close to that of the fiber and ferrule. This means the connection stays stable even as temperatures change.

- Stable and Hard: It is chemically inert and very hard, resisting wear over a long lifespan.

Why China Dominates the SC Sleeve Market

When you search for an SC type ceramic sleeve China supplier, the number of results is overwhelming. This is no accident. China has built a massive ecosystem for producing high-volume, high-precision fiber optic components.

Massive Economies of Scale

The sheer volume is staggering. Chinese factories produce billions of these sleeves per year. This scale drives down the cost of everything. Raw materials are bought in bulk. Automated production lines run 24/7. The cost per part becomes very low, making it difficult for other regions to compete on price.

A Mature, Vertically-Integrated Supply Chain

A manufacturer in Shenzhen or Wuhan does not exist in a vacuum. They are supported by a complete local supply chain. This includes:

- Raw Material Processors: Companies that refine and mill the high-purity zirconia powder.

- Tooling and Mold Makers: Factories that specialize in creating the high-precision injection molds.

- Specialized Equipment: Businesses that build and maintain the specific grinding, polishing, and slotting machines.

- Testing Labs: Local facilities that can perform advanced material analysis.

This integration means a factory can source parts, fix machines, and ship products with great speed.

Decades of Technical Expertise

China's massive rollout of Fiber-to-the-Home (FTTH) networks created a huge internal demand. This demand forced manufacturers to get very good, very fast. They have spent the last two decades perfecting the high-volume manufacturing of zirconia parts. This expertise is now exported to the world.

While China leads in volume, other regions have their own specializations. For example, sourcing ceramic sleeves in the USA often relates to specialized military, medical, or aerospace parts. Likewise, sourcing ceramic sleeves in Europe may involve high-end automotive or industrial machinery.

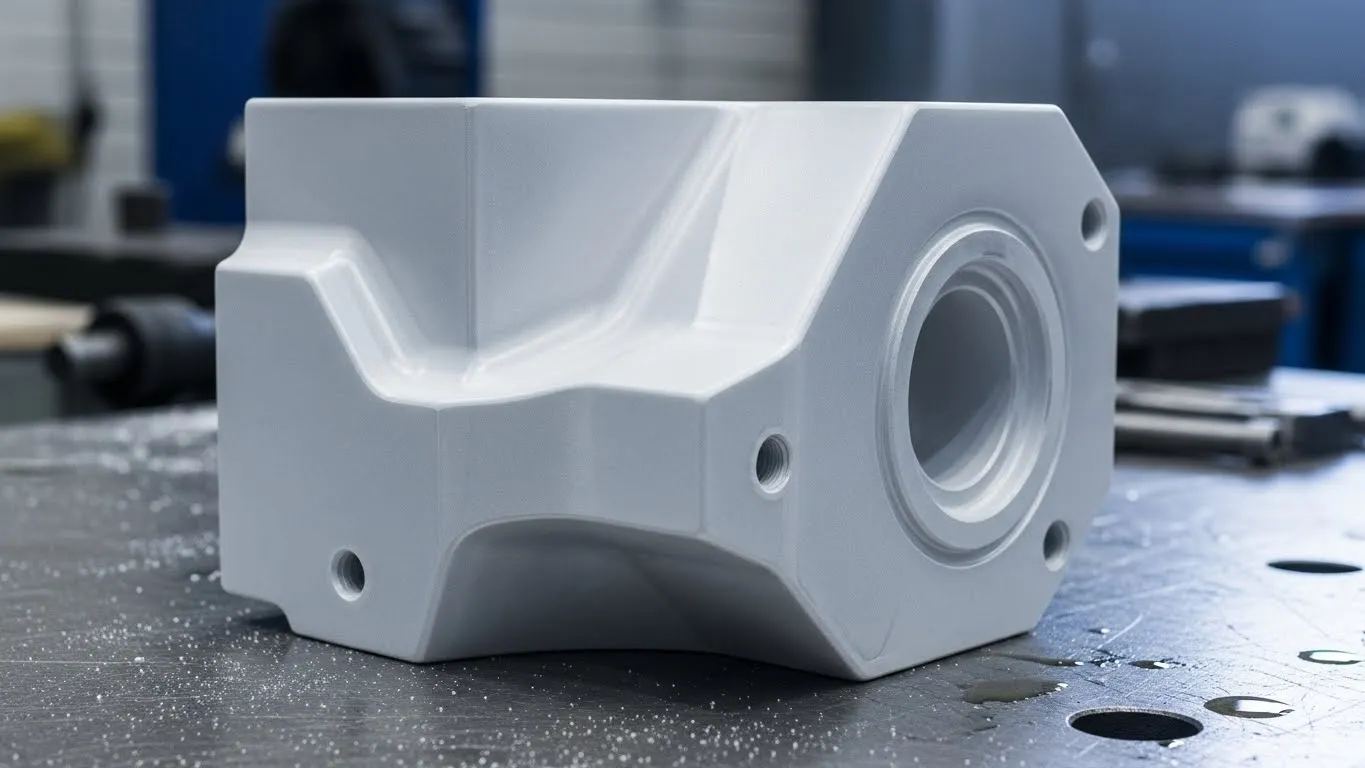

The Manufacturing Process: From Powder to Precision Part

Understanding how an SC sleeve is made helps you ask better questions. A good manufacturer will be transparent about their process.

How are SC ceramic sleeves made?

SC ceramic sleeves start as fine zirconia powder. This powder is mixed with a binder and formed using ceramic injection molding. The "green part" is then fired at high heat (sintered) to become hard. Finally, it is precision-ground, slotted, and polished to exact micron-level tolerances.

Step 1: Raw Material Preparation

The process begins with high-purity zirconia powder. The powder is mixed with a proprietary binder (a type of polymer) to create a feedstock. This feedstock has the consistency of a thick paste, which allows it to be molded.

Step 2: Ceramic Injection Molding (CIM)

The feedstock is heated and injected under high pressure into a multi-cavity mold. This is just like plastic injection molding but far more precise. This step creates the "green part." The green part is larger than the final sleeve because it will shrink during the next step.

Step 3: Sintering

This is the most critical stage. The green parts are placed in a high-temperature kiln. The temperature is slowly raised in a controlled atmosphere.

- Binder Burnout: First, the polymer binder is slowly burned away.

- Sintering: As the temperature rises (often over 1400°C), the zirconia particles fuse. The part shrinks by 20-25% and becomes incredibly hard and dense.

A poor sintering process leads to internal cracks, low density, and brittle parts.

Step 4: Precision Grinding

The sintered part is hard, but its dimensions are not yet perfect. It must be ground using diamond tools.

- Outer Diameter (OD) Grinding: The part is spun and ground to its precise outer diameter.

- Inner Diameter (ID) Grinding: A tiny, spinning diamond-coated pin is used to grind the inner bore. This is the most difficult and important step.

Step 5: Slotting

A high-precision diamond saw is used to cut the thin split down the length of the sleeve. The width of this slot is a critical specification.

Step 6: Polishing and Lapping

The parts are tumbled or lapped with a fine diamond slurry. This smooths the inner and outer surfaces, removes any microscopic burrs from grinding, and creates a very low surface roughness.

Step 7: Final Cleaning and Inspection

Finally, the sleeves are put through an ultrasonic cleaning process to remove all polishing residue. After cleaning, they go to Quality Control for 100% inspection.

Quality Control: The Difference Between a Good and Bad Sleeve

A cheap SC sleeve is not a good deal. A bad sleeve causes signal loss, damages connectors, and leads to network failure. A top-tier SC type ceramic sleeve China manufacturer focuses on quality control above all else.

Here are the key metrics they measure.

Dimensional Accuracy

This is the top priority. We are talking about measurements in microns (µm). A human hair is about 70 µm wide. A good sleeve's tolerance is often $\pm$1 µm.

- Inner Diameter (ID): This is the most critical spec. For single-mode SC sleeves, the ID is typically 1.250 mm (for LC) or 2.500 mm (for SC ferrules), but the precision on that number is key.

- Concentricity: This measures how perfectly centered the inner hole is relative to the outer wall. Poor concentricity means the fibers will be offset, causing signal loss.

Insertion and Retention Force

This test measures the "springiness" of the sleeve. A steel pin gauge of a precise diameter is inserted and pulled out.

- Insertion Force: The force needed to push the pin in. If it is too high, it can damage the fiber.

- Retention Force: The force needed to pull the pin out. If it is too low, the connection is not secure and can be disrupted by vibration.

A good manufacturer will provide a data report showing these forces are within a tight range (e.g., 2.0 - 5.9 N).

Surface Roughness (Ra)

A profilometer is used to measure the smoothness of the inner bore. A rough surface can scratch the fiber ferrule's end-face. A smooth, polished surface (low Ra) is essential for a reliable connection.

Visual Inspection

Every single sleeve is checked under a microscope or with an automated optical inspection (AOI) system. Inspectors look for:

- Micro-cracks: Any small fractures from the sintering or grinding process.

- Chips: Flakes or chips on the end-faces or at the slot.

- Burrs: Small pieces of ceramic material left over from grinding.

- Contamination: Any specks of dust or polishing material.

How to Vet an "SC Type Ceramic Sleeve China" Manufacturer

You have a list of 20 potential suppliers. How do you find the right one? You must act like a detective.

1. Are They a Manufacturer or a Trading Company?

This is the most important question. A trading company is just a middle-man. A manufacturer makes the part.

- How to check:

- Ask for a factory tour. Even a live video call tour is revealing. A trader will make excuses.

- Ask for their business license. It will state their business scope (e.g., "production," "manufacturing").

- Ask for their core process. Ask them, "What is your sintering temperature for zirconia?" A manufacturer will answer. A trader will have to ask someone else.

2. Ask for Certifications

Legitimate manufacturers invest in quality systems. Ask for copies of their certificates.

- ISO 9001:2015: This is the global standard for a quality management system. It is a basic requirement.

- RoHS: This (Restriction of Hazardous Substances) is essential if you sell products in Europe.

- REACH: Another European regulation regarding chemicals.

3. Request Samples (And Test Them)

This is the ultimate test. Do not just look at the sample. Test it.

- Ask for 100-200 pieces.

- Give them to your engineering team.

- Test their insertion/retention force.

- Use them to build sample connectors and test the insertion loss (IL) and return loss (RL).

- Check them under your own microscope for a quality look and feel.

4. Ask for Their Quality and Inspection Reports

A good factory is proud of its data. Ask for two things:

- A sample internal inspection report. This shows you what they measure for their own internal quality control.

- A Certificate of Conformance (CoC) or OQC (Outgoing Quality Control) report. This is the document they would send with your shipment. It should list the key dimensions and test results for that specific batch.

5. Evaluate Their Technical Communication

Send them a technical question. "What is the concentricity tolerance for your 2.50 mm sleeve?" or "What is your standard insertion force range for a 1.249 mm pin gauge?"

- A good supplier: Will give you a fast, clear, and correct answer. Their engineers likely speak some English.

- A bad supplier: Will be confused, give a vague answer, or have to wait two days to get an answer.

Common Problems When Sourcing (And How to Avoid Them)

Sourcing from any SC type ceramic sleeve China manufacturer is not without risks. Here are the most common problems.

- The Problem: Inconsistent Quality. The samples are perfect. Your first order is great. Your sixth order has a 10% failure rate.

- The Solution: Have a formal "Quality Agreement" or "Specification Sheet." This document locks in all the critical specs (ID, OD, concentricity, insertion force, etc.). Both you and the supplier sign it. This becomes your contract.

- The Problem: "Bait and Switch." They send you samples made from high-grade Japanese zirconia powder. Your production order is made with a cheaper, low-grade domestic powder. The parts look the same but are more brittle.

- The Solution: This is tough to catch. Your "Quality Agreement" should specify the material. Testing your connectors' performance is the best defense. A drop in performance is a big red flag.

- The Problem: Shipping and Damage. The parts are good, but they arrive in a flimsy box, all jumbled together, and 5% are chipped.

- The Solution: Specify your packaging. High-precision sleeves should be shipped in "gel packs" or custom-molded plastic trays to prevent them from touching each other.

Beyond the SC Sleeve: The Broader Ceramic Market

The expertise in China is not limited to just SC sleeves. This technical know-how applies to a wide range of components.

- LC and MU Sleeves: The smaller sleeves for small form-factor connectors.

- Other Fiber Optic Parts: Zirconia ferrules, MT ferrules, and other alignment components.

- Industrial Ceramics: This same technology is used to make other industrial parts. You can find suppliers for ceramic tube sleeves in Indonesia for thermal protection or even ceramic fiber sleeves from Japan for high-temperature insulation. The ecosystem for ceramic fiber components in Indonesia is often supplied by these same global ceramic powerhouses.

For a complete overview of all the different types of sleeves, see our ceramic sleeves guide.

The Global Context: China vs. The World

- China: The undisputed leader for high-volume, cost-effective fiber optic components.

- India: The market for a ceramic sleeves supplier in India is growing rapidly to meet its own massive internal demand for telecom infrastructure.

- Japan: Still seen as a leader in raw material (zirconia powder) and ultra-high-precision, next-generation components.

- USA/Europe: Focus on lower-volume, higher-margin specialty ceramics for medical, defense, and industrial automation.

Future Trends in Ceramic Sleeve Manufacturing

The technology is not standing still. The push for 800G and 1.6T data rates demands even better connections.

What is the future of fiber optic sleeve manufacturing?

The future of sleeve manufacturing is focused on tighter tolerances, more advanced materials, and 100% automation. As data speeds increase, alignment becomes more critical, driving the need for sub-micron precision. New ceramic composites will also offer greater toughness and stability.

- Tighter Tolerances: The demand for $\pm$0.5 µm tolerances will become standard.

- Increased Automation: 100% automated optical inspection (AOI) will replace human inspectors to catch smaller defects at higher speeds.

- Advanced Materials: Research into new materials, like Ceramic Matrix Composites (CMCs), may lead to even tougher, more stable components for harsh environments.

Final Checklist for Sourcing SC Ceramic Sleeves in China

You are now ready to start your search. Use this as your final checklist.

- Define Your Specification: Do not just ask for an "SC sleeve." Ask for a "2.50 mm Zirconia Sleeve, OD 3.197 mm, Length 11.4 mm, Insertion Force 2.0-5.9 N with 2.499 mm pin gauge." Be specific.

- Separate Manufacturers from Traders: Use the video tour and factory audit questions.

- Get Samples. Test Samples. Do not skip this step. Ever.

- Demand Quality Data: Ask for the inspection report and CoC.

- Create a Quality Agreement: Lock in the specifications before you place a large purchase order.

Following this process will take more effort than just picking the cheapest supplier on Alibaba. But it will save you from network failures, field returns, and a damaged reputation. It is the foundation for building a reliable, high-performance product.

In This Article

- 1 What Exactly is an SC Type Ceramic Sleeve?

- 2 Why China Dominates the SC Sleeve Market

- 3 The Manufacturing Process: From Powder to Precision Part

- 4 Quality Control: The Difference Between a Good and Bad Sleeve

- 5 How to Vet an "SC Type Ceramic Sleeve China" Manufacturer

- 6 Common Problems When Sourcing (And How to Avoid Them)

- 7 Beyond the SC Sleeve: The Broader Ceramic Market

- 8 Future Trends in Ceramic Sleeve Manufacturing

- 9 Final Checklist for Sourcing SC Ceramic Sleeves in China

English

English 中文

中文