Ultra-Hard Ceramic Machining Challenges and Proven Cutting Solutions

Ultra-Hard Ceramic Machining is the precision shaping, grinding, and finishing of advanced ceramics (e.g., zirconia, alumina, SiC, Si₃N₄) using diamond tools, rigid fixturing, and controlled parameters to achieve tight tolerances, smooth surfaces, and minimal subsurface damage. Yet even strong teams can feel squeezed by tight windows and fragile margins. Tools wear faster than expected. A clean edge turns into a chipped exit. A stack of parts passes dimensional checks but later fails due to subsurface damage. From UPCERA's vantage point - as a manufacturer focused on the customization and processing of advanced ceramic materials - these problems are common, predictable, and fixable. What follows is a practical view of where projects go off the rails and how we help customers move from trial-and-error to stable, scalable output.

Why Ultra-Hard Ceramic Machining Trips Up Good Teams

Most failures do not come from "impossible materials.” They come from narrow process windows that nobody locked down. Zirconia and other advanced ceramics combine high strength with real fracture toughness, but they punish spikes in load and heat. When coolant delivery is inconsistent or a fixture has a little flex, the edge pays the price. Scrap rises, cycle time stretches, and trust in the process erodes.

Surface integrity is the quiet cost driver. A part may look flawless after finishing, yet microcracks or a damaged layer below the surface can shorten wear life, worsen sealing performance, or undermine biocompatibility in medical use. Geometry multiplies the risk: thin walls, tight radii, and blended features amplify every small mistake in feeds, speeds, and wheel condition. The shop that can make one showcase part still may not be ready for 10,000 identical pieces.

In Ultra-Hard Ceramic Machining, stability must come before speed. Push feeds too hard and subsurface damage blooms. Go too light and you burn hours without improving quality. The path to confidence is boring - controlled removal, rigid fixturing, healthy wheels, consistent coolant, and inspection that focuses on what matters.

- The Hidden Cost Drivers We See Most Often

• Premature tool wear that slowly drifts Ra and raises unit cost

• Edge chipping on exits, slots, and small, high-aspect-ratio features

• Tight tolerances that collapse under thermal or clamping variation

• Subsurface damage revealed only during testing or in the field

How UPCERA Stabilizes The Process

UPCERA treats Ultra-Hard Ceramic Machining as an engineered system rather than a list of parameters. We tune the machining route and the part together. That often means changing the order of operations, adjusting how a feature is supported, or choosing a finishing sequence that protects edges instead of punishing them.

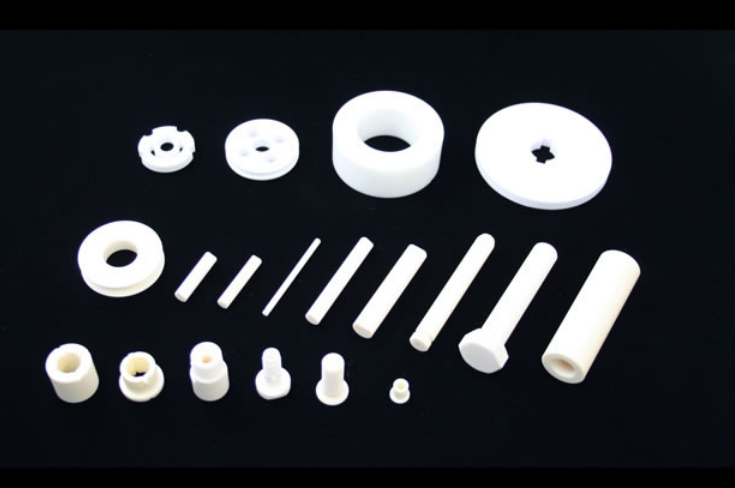

Our specialization is custom zirconia ceramic parts manufacturing for industries that cannot compromise - medical, precision instruments, electronics, aerospace, automotive, and general manufacturing. Zirconia (ZrO₂) brings high mechanical strength, notable fracture toughness, and thermal stability. When combined with the right fixtures and finishing, it delivers excellent surface finish and tight tolerances, even in high-friction or high-temperature settings. Zirconia is biocompatible and inert for surgical tools, dental components, and laboratory parts that face sterilization. It is also non-conductive and non-magnetic, which makes it a natural fit for electrical insulation and magnetically sensitive systems.

Rather than chase aggressive feeds, we start by removing variation. Fixturing supports the part where it is weakest - thin walls, narrow webs, and sharp transitions. Wheel selection and dressing focus on clean cutting and thermal control. Coolant is delivered where it does real work, not just where it is easy to plumb. Inspection closes the loop with attention to edge integrity and surface condition, not only size.

✅ What You Can Expect With UPCERA

• High strength and fracture toughness leveraged for durable, stable parts

• Excellent surface finish and tight tolerances for precision fits

• Wear and corrosion resistance that protects critical interfaces

• Biocompatibility suited to surgical tools, implants, and dental pieces

• Customized shapes and complex geometries produced with repeatable accuracy

• Exceptional thermal and chemical stability for harsh environments

• Non-conductive, non-magnetic behavior for sensitive equipment

Material And Design Choices That Pay Off

Small design moves can prevent big manufacturing headaches. If a sharp internal corner becomes a controlled fillet, edge life improves and the finishing pass becomes safer. If a critical face becomes the primary datum, inspection tightens and rework falls. Early design-for-manufacture reviews let us place stock where it supports the route and remove it where it creates heat or chatter.

Our precision zirconia ceramic machining services focus on predictable removal first, then speed. We protect edges during finishing, support delicate features during roughing, and balance allowances so polishing does not chase geometry. The result is a smoother ramp from prototype to production with fewer surprises and a clearer cost model.

Where These Parts Work - And Why They Last

Ultra-hard ceramic components do their best work when the environment is tough and repeatability matters. In medical and dental devices, zirconia's biocompatibility and clean polish support sterilization and long service life. Precision instrumentation values stability and wear resistance that hold calibration. Semiconductor and electronics equipment benefit from insulating components that play nicely with cleanroom requirements. Industrial machinery and robotics lean on zirconia guides, bushings, and nozzles that tolerate friction and temperature swings. Aerospace and automotive programs choose zirconia for strength-to-weight and for features that face vibration and thermal cycling. Chemical processing and energy systems rely on seals and structural supports that survive corrosive or hot conditions.

Not every feature needs a boutique operation. Thoughtful tolerance allocation, sensible datum structures, and a finishing path that respects edges will lower cost while improving reliability. We work side by side with your engineers to align surface finish targets with function, to place datums where inspection is strongest, and to set material allowances that avoid over-polishing. The outcome is straightforward production, easier qualification, and fewer stops on the way to volume.

Ultra-Hard Ceramic Machining is demanding, but it rewards discipline. When load, heat, and support are under control, tool life stabilizes, finishes become consistent, and complex geometries stop being cost traps. That is the point where programs scale without drama - and where zirconia's strengths truly show up in the field.

Closing Words

Wrestling with edge chipping, tool wear, or unstable finishes? Share your drawing, target tolerances, and application with UPCERA. We will propose a manufacturable route for Ultra-Hard Ceramic Machining - from material choice through finishing - so you can ship dependable parts with confidence.

English

English 中文

中文