How Wear-Resistant Ceramic Parts Improve Machine Lifespan

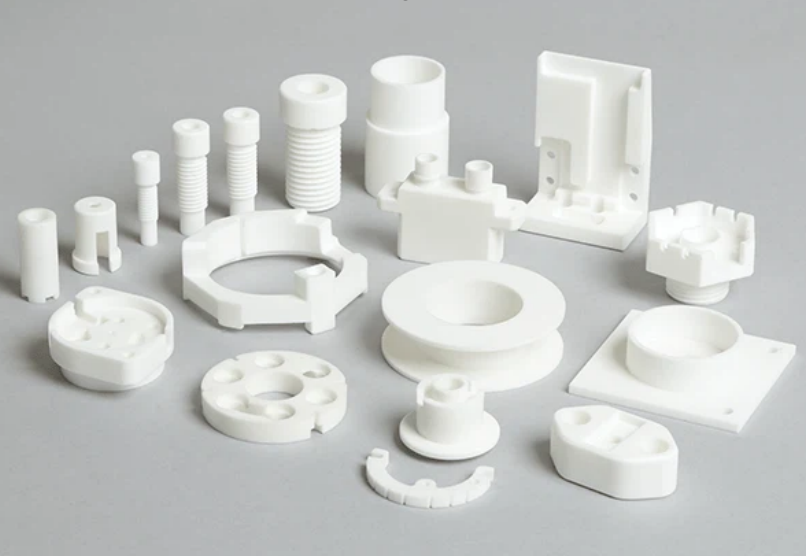

Wear-Resistant Ceramic Parts are the quiet safeguard that stretch machine life by standing up to abrasion, corrosion, and heat while metals fatigue. At UPCERA, we design and manufacture advanced ceramics that keep equipment stable, reduce unplanned stops, and protect the tolerances that make a line profitable. Our view is straightforward: longevity starts with the right material - and careful workmanship at every step.

From Failure Modes to Longer Service Life

Unexpected downtime rarely has a single cause; it's a chain of small losses. Sliding faces polish away, bearings score under fines, corrosive fluids pit housings, and thermal cycling loosens fits. Each weak point steals accuracy and forces maintenance earlier than planned. This is exactly where Wear-Resistant Ceramic Parts change the curve, because they hold geometry and surface integrity in places where metals give up speed.

In the field, black zirconia - derived from zirconium dioxide (ZrO₂) - has proven especially effective. It offers high mechanical strength and fracture toughness, so parts resist cracking even under heavy loads. The material's black color comes from controlled processing or stabilizers and does not alter core performance. That visual contrast is useful when components must be seen and aligned quickly, and it brings a premium finish to products where aesthetics matter alongside function.

✅ Typical Wear Patterns We Replace

• Grooved bushings and guides that shed debris into motion systems

• Bearing seats that lose roundness under abrasive media

• Exposed housings attacked by corrosive cleaning fluids

• Small precision parts that drift out of spec due to heat cycles

✅ Why Ceramics Outlast Metals

Metals deform and wear because their strength depends on ductility and coatings that erode. Ceramics, by contrast, rely on intrinsic hardness, chemical stability, and a surface that maintains its finish under severe contact. When you reduce friction and preserve dimensions, you reduce heat, chatter, and rework. That is the simple logic behind longer service intervals and more predictable output.

Black Zirconia: The UPCERA Approach

We treat black zirconia as a system, not just a material. Our engineering team begins with load paths, contact conditions, and mating parts. We then match geometry and finish to the job - because durability depends on the details you can't see once a part is installed. The result is Wear-Resistant Ceramic Parts that tolerate harsh duty without drifting from spec.

- Material Fundamentals

Black zirconia maintains exceptional strength and fracture toughness. It exhibits excellent wear resistance in abrasive flows and strong corrosion resistance in aggressive chemicals. Thermal and chemical stability support consistent performance in environments that swing hot, cold, or both. The material also provides electrical insulation and magnetic neutrality, which helps in sensitive electronics and magnetically influenced assemblies. None of these properties are compromised by the black coloration process; performance remains built into the crystal structure.

- Precision and Finish

A long-lived component is more than a hard material. It is a surface that stays smooth and an interface that aligns cleanly. We supply tight tolerances across tubes, plates, rings, and custom shapes, then finish surfaces to reduce friction and protect the mating element. That combination lowers heat and stabilizes motion, which is why customers often see cleaner run-in behavior and fewer post-maintenance adjustments.

✅ Design Support That Pays Back

• We translate operating conditions into geometry, clearances, and finish choices

• We recommend drop-in replacements for short-lived metal wear items

• We validate tolerances across batches for repeatable assemblies

• We support custom production when complex shapes or tight envelopes are required

Real-World Uses and Next Steps

The promise of longer life must show up on the line. In precision machinery, our ceramic bushings, bearings, guides, and wear plates maintain alignment when lubricants carry fine particulates or when cycle rates climb. Their stable surface helps protect the shaft or rail they touch, cutting secondary damage that usually forces early rebuilds. A practical long-tail phrase here - wear-resistant ceramic bushings for high-temperature equipment - captures how often heat and abrasion show up together in real systems.

In medical and dental tools, clean edges and durability support reliable performance. Electronics and consumer products benefit from sturdy housings, rings, and cosmetic components that keep their premium look. Aerospace and defense teams choose black zirconia for vibration-prone and high-temperature zones, where toughness and thermal stability matter. Automotive designers use ceramic parts in sensor mounts and engine-adjacent features that face both heat and wear. Optical and laser systems leverage the black finish to reduce glare while preserving precise dimensions.

Not every improvement requires a redesign. Many customers begin by swapping the highest-wear metal component for a ceramic equivalent. We match the existing geometry or make a small change that protects the true contact area. Over a few maintenance cycles, this single substitution often stabilizes output quality and lengthens the time between interventions. The benefits are cumulative: less debris, fewer alignment issues, and more consistent product.

✅ What Longer Life Looks Like on the Line

• Tolerances that stay in spec through abrasive runs

• Fewer surface defects, less rework, smoother motion

• Higher reliability in corrosive or high-temperature zones

• Aesthetic contrast for visible components without sacrificing strength

The aesthetic benefit is worth calling out. The premium black appearance isn't just “nice to have.” On instruments, panels, or bezels, it signals quality while still delivering mechanical value. For teams balancing brand and performance, black zirconia closes the gap between what looks right and what lasts.

From the UPCERA side, our process is built around manufacturability and stability. We collaborate early, confirm the boundary conditions, and select a path that keeps the part strong without complicating assembly. Where a polished finish matters, we use the right finishing steps to achieve low friction and gentle contact. Where alignment dominates, we hold tight tolerances and verify them across production lots. The goal is simple: reliable parts that install once and keep working.

Call to Action

If you're ready to cut unplanned stops and protect critical tolerances, talk with UPCERA about your wear points. Share operating conditions, target dimensions, and current failure modes. We'll suggest Wear-Resistant Ceramic Parts - often in black zirconia - that strengthen the contact zone, maintain alignment, and extend machine lifespan without reengineering your whole assembly. Let's turn recurring maintenance into sustained performance - one durable component at a time.

English

English 中文

中文