Zirconia Ceramic Ferrule Supplier Europe

A premier zirconia ceramic ferrule supplier Europe is an essential partner for high-technology industries. These suppliers provide the most critical component in modern fiber optic networks. The ferrule is a microscopic, high-precision pin. It is made almost exclusively from zirconia. Its sole function is to align optical fibers. The performance of an entire data network rests on the sub-micron precision of this single component.

The European market, in particular, demands the highest standards. A supplier here must provide more than just a component. They must deliver a guarantee of quality. This includes material purity, dimensional consistency, and full compliance with strict regulations. These suppliers are a vital link in the supply chain. They connect global manufacturing with local, high-specification projects. This includes data centers, 5G rollouts, and advanced medical technology.

What Is a Zirconia Ceramic Ferrule?

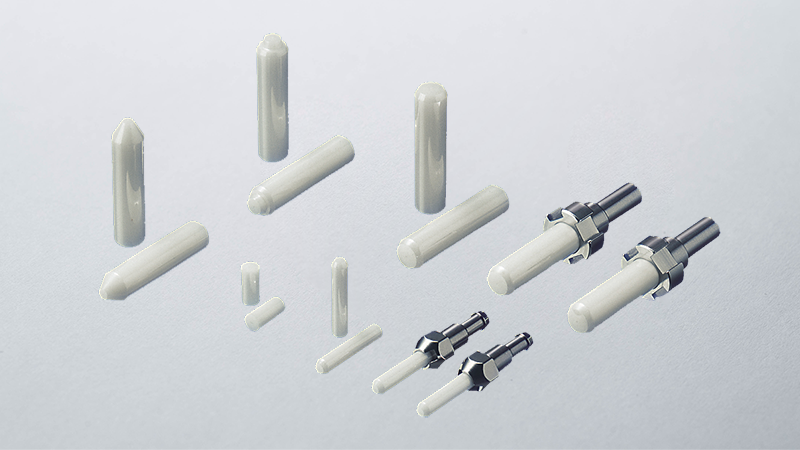

A zirconia ceramic ferrule is the heart of a fiber optic connector. It is a small, rigid, cylindrical component. It has a microscopic hole, or "bore," through its exact center. This component's job is to hold a single, bare optical fiber. It protects the delicate glass fiber. It also provides a stable, polished end-face.

The Core of Fiber Optic Connectors

When two connectors are mated, two ferrules are pressed together. A spring mechanism ensures they make physical contact. This action aligns the two fiber cores. This alignment must be nearly perfect. It allows a beam of light to pass from one fiber to the other. Any error in this alignment causes signal loss.

The Precision Alignment Mechanism

The ferrule is the primary alignment mechanism. Its precision is the single most important factor in connector performance. A single-mode fiber core is only 9 microns in diameter. This is smaller than a human blood cell. The ferrule must align these cores with sub-micron accuracy. This is why it is a high-technology component.

Why Not Metal or Plastic?

Early connectors used metal or plastic ferrules. These materials failed.

- Metal: Metal ferrules would scratch easily. They also expand and contract with temperature. This would break the fiber or cause misalignment.

- Plastic: Plastic ferrules are imprecise. They are not suitable for single-mode fiber.

Zirconia solved all of these problems. It became the undisputed industry standard. A complete ceramic ferrules guide will confirm this.

The Unmatched Properties of Yttria-Stabilized Zirconia (Y-TZP)

The component is named for its material. A zirconia ceramic ferrule supplier Europe almost exclusively stocks parts made from Yttria-Stabilized Zirconia (Y-TZP). This is an advanced technical ceramic. It is not a natural material. It is a product of sophisticated ceramic engineering.

Y-TZP: The Gold Standard Material

Zirconia in its pure form is unstable. It changes crystal structure with temperature. Yttria is added as a "stabilizer." This locks the zirconia into a strong, stable tetragonal crystal structure. This Y-TZP material is the gold standard.

Extreme Hardness and Durability

Zirconia is exceptionally hard. It has a hardness of around 8.5 on the Mohs scale. This is much harder than steel. This hardness is vital for the ferrule's end-face. It means the polished tip will not scratch or deform. A connector can be mated and un-mated thousands of times. The ferrule will not wear out.

High Fracture Toughness

This is zirconia's most unique trait. Most ceramics, like a dinner plate, are brittle. They shatter. Zirconia is "tough." It can absorb stress and impact. This is due to a process called "transformation toughening." If a micro-crack forms, the zirconia crystal structure changes at the tip of the crack. This change absorbs the energy and stops the crack from growing. This toughness is essential for a small, spring-loaded part.

Critical Thermal Stability

This is the most important property for performance. Zirconia has a coefficient of thermal expansion of around 10 x 10⁻⁶/°C. This is very close to that of the glass optical fiber. This similarity is critical. It means that as the equipment heats up and cools down, the ferrule and the fiber expand and contract at almost the same rate. This prevents the fiber from breaking. It also stops "pistoning," which would create a gap and kill the signal.

Chemical Inertness and Reliability

Zirconia is a stable oxide. It does not rust, corrode, or react with moisture. This ensures the component will have a long, reliable life. It will perform for decades in any environment.

The Role of a Premier European Supplier

A premier zirconia ceramic ferrule supplier Europe is not just a reseller. They are a critical supply chain and quality partner. They add significant value.

More Than a Reseller

A reseller moves boxes. A premier supplier provides solutions. They are a technical partner. We help customers select the right grade of ferrule. They help troubleshoot polishing and testing issues.

Bridging Global Manufacturing and Local Needs

Ferrule manufacturing is a highly specialized, capital-intensive process. It is concentrated in a few key global hubs. A European supplier bridges this gap. They manage the global supply chain. This allows a local assembler to access the world's best components.

The Importance of Local Inventory

This is the supplier's most immediate value. A top supplier holds a deep, local inventory. They stock millions of ferrules. This includes 2.5 mm, 1.25 mm, PC, and APC types. This local stock is a major advantage.

- Fast Delivery: Customers get parts in days, not 12 weeks from an overseas factory.

- No Import Hassles: The supplier handles all importation, customs, and duties.

- Just-in-Time (JIT) Supply: Assemblers can pull stock as needed. This reduces their own inventory costs.

Technical Expertise and Support

A local supplier understands the market's needs. Their technical team is in the same time zone. They can provide immediate, expert support. This is invaluable when a production line is down.

A zirconia ceramic ferrule supplier Europe must be an expert in compliance. This is a non-negotiable part of their business. The European market is one of the strictest in the world.

Understanding Strict Regulatory Demands

A supplier must guarantee that every product they sell is 100% compliant. This is a legal requirement. Failure to comply can result in large fines and products being removed from the market.

What is the RoHS Directive?

RoHS stands for Restriction of Hazardous Substances. This directive restricts the use of ten specific materials in electronic equipment. This includes lead, mercury, cadmium, and certain phthalates. A ceramic ferrule, as a component, must be certified free of all these substances.

What is the REACH Regulation?

REACH stands for Registration, Evaluation, Authorisation and Restriction of Chemicals. This is a much broader regulation. It controls the use of all chemical substances. A supplier must be able to provide a Declaration of Conformity. This document states that their products do not contain any "Substances of Very High Concern" (SVHC) above the legal limit.

The Supplier's Role in Compliance

The supplier is the gatekeeper for compliance. They are responsible for:

- Auditing their manufacturers' material sources.

- Collecting and verifying all compliance documents.

- Providing a full, traceable paper trail to the customer.

This service is a key part of the value they provide.

Documentation and Traceability

A premier supplier provides full lot traceability. This means a batch of ferrules can be traced back to its manufacturing date. It can also be traced to the raw material powder batch. This is essential for quality control.

Manufacturing: From Powder to Sub-Micron Precision

A supplier must be an expert in the manufacturing process. This is how they vet their partners. The creation of a zirconia ferrule is a multi-stage process.

Step 1: Formulation of Zirconia Powder

The process begins with an ultra-pure, nanoscale Y-TZP powder. This powder is mixed with a proprietary polymer binder. This creates a feedstock material. The binder acts as a temporary "glue" that allows the powder to be molded.

Step 2: Ceramic Injection Molding (CIM)

The feedstock is heated until it has a paste-like consistency. It is then injected under very high pressure into a steel mold. This mold has the shape of the ferrule. It is, however, about 20% larger than the final part. This is to account for shrinkage. This molding process creates the "green part."

Step 3: Debinding and Sintering

This is the most critical and time-consuming stage.

- Debinding: The green part is placed in a furnace. It is heated very slowly. This process carefully burns away the polymer binder. This must be done gradually, or the part will crack.

- Sintering: The part is then heated to an extreme temperature. This is often over 1,400°C. The part is now just porous zirconia. At this heat, the zirconia particles fuse. The part shrinks by a precise amount. It becomes incredibly hard, dense, and chemically stable.

Step 4: Precision Grinding (OD)

After sintering, the ferrule is hard, but its dimensions are not yet perfect. It must be finished. A centerless grinder is used. This machine uses diamond wheels. It grinds the outer diameter to its exact 2.5 mm or 1.25 mm size. The tolerance is often ±0.0005 mm (half a micron).

Step 5: Bore Lapping (ID)

This is the most difficult and proprietary step. The microscopic hole in the center must be finished. A precision wire, coated in diamond slurry, is often used. It "laps" the inner hole. It removes material one nanometer at a time. This step establishes the final inner diameter. It also ensures the hole is perfectly straight.

Step 6: 100% Inspection and Metrology

Every single ferrule is inspected. This is not batch sampling. 100% of the parts are checked. Automated systems use air gauges, lasers, and video cameras. They check the ID, OD, and concentricity. Any part that is not perfect is discarded.

Key Ferrule Specifications and Standards

A zirconia ceramic ferrule supplier Europe provides parts that meet exact, verifiable numbers. Quality is not subjective.

The Language of Precision

A supplier must be fluent in the language of precision. They must be able to provide parts that meet these grades.

Ferrule Outer Diameter (OD): 2.5 mm

This is the older, larger standard. It is the-pin used in SC, ST, and FC connectors. These are known for their robust, durable nature. They are still common in telecom and industrial applications.

Ferrule Outer Diameter (OD): 1.25 mm

This is the smaller, modern standard. It is used in LC and MU connectors. Its small size allows for very high-density connections. This makes it the standard for data centers and 5G.

Inner Diameter (Bore) Tolerance

The inner diameter (ID) must match the fiber. A standard 125 µm fiber uses a ferrule with a 126 µm bore. This provides a 1 µm clearance. This tolerance is critical.

- Standard ID: 126 µm (±1.0 µm)

- Precision ID: 126 µm (±0.5 µm)

A tighter tolerance improves alignment.

Understanding Bore Concentricity

This is the most critical specification for performance. Concentricity is the measure of how centered the ID (the hole) is relative to the OD (the ferrule body). Any offset is called eccentricity.

The Impact of Eccentricity on Loss

This eccentricity directly causes the fiber cores to be misaligned. A 1 µm offset can cause 0.5 dB of signal loss. This is unacceptable. Ferrules are graded based on this metric.

- Standard Grade: May have an eccentricity of 1.0 µm or more.

- Premium Grade: Will have an eccentricity of < 0.7 µm.

- Ultra Grade: Will have an eccentricity of < 0.5 µm.

A premier supplier will only stock premium and ultra grades.

End-Face Geometry: Physical Contact (PC)

This is the standard, flat-polished ferrule. It is actually polished to a slight dome shape. This ensures the fiber cores make physical contact.

End-Face Geometry: Ultra Physical Contact (UPC)

This is a PC ferrule that is polished to a finer, better surface finish. This reduces back reflection.

End-Face Geometry: Angled Physical Contact (APC)

The end of the ferrule is polished at an 8-degree angle. This is the green connector. The angle causes any reflected light to bounce out of the fiber. This prevents back reflection. It is essential for video, 5G, and high-speed data. A supplier must stock these pre-angled ferrules.

Telcordia Standards and Performance Grades

Suppliers in this market provide parts that help assemblers meet Telcordia standards. These are a set of reliability and performance standards for telecom equipment.

Quality Assurance: The Supplier's Guarantee

A top-tier supplier takes quality assurance very seriously.

- Verifying ISO 9001: They ensure their manufacturing partner is ISO 9001 certified.

- In-House Metrology: A premier supplier has its own test lab.

- Material Traceability: They must provide full lot traceability.

How Air Gauges Verify Inner Diameter

An air gauge is a non-contact tool. It blows a precise amount of air through the ferrule's bore. By measuring the back pressure, it can calculate the inner diameter to sub-micron accuracy.

How Interferometers Check End-Face

An interferometer is a light-based tool. After polishing, it is used to check the end-face geometry. It ensures the polish angle (for APC) or the dome shape (for PC) is perfect.

The Global Context of Zirconia Ferrule Sourcing

A zirconia ceramic ferrule supplier Europe operates in a global market.

- They source from the world's best manufacturers. These are often in high-volume hubs like those for ceramic ferrules China.

- They benchmark their quality against other high-spec markets, like those for ceramic ferrules USA.

- They are part of the wider ceramic ferrules Europe supply network.

- They also support growth in other regions. This includes markets for ceramic ferrules India and ceramic ferrules Indonesia.

This global perspective allows them to provide the best products and a stable supply.

How to Evaluate a Zirconia Ceramic Ferrule Supplier

When selecting a partner, a buyer should use a checklist.

- ISO 9001 Certification: Is the supplier ISO 9001 certified?

- RoHS and REACH Compliance: Can they provide a Declaration of Conformity?

- Local Stockholding: Do they have a significant local inventory?

- Technical Support: Do they have an engineering team?

- Test Data: Can they provide a test report for the ferrules?

- Traceability: Can they offer full lot traceability?

Red Flags to Watch For

- No Compliance Documents: A supplier who cannot provide RoHS/REACH data is a major risk.

- No Technical Data: A supplier who cannot provide a specification sheet is not a professional.

- Unusually Low Price: A price that is too good to be true often is. It likely means the part is made from impure zirconia or has not been 100% inspected.

Conclusion

A zirconia ceramic ferrule supplier Europe is a strategic partner. They are not just a supplier. We are an extension of their customer's quality team. They provide a secure, compliant, and reliable supply of the most critical component in fiber optics. The material, zirconia, is a modern marvel. Its properties make our connected world possible. By managing local stock, providing technical support, and ensuring 100% compliance, these suppliers enable the region's technology industry to thrive.

In This Article

- 1 What Is a Zirconia Ceramic Ferrule?

- 2 The Unmatched Properties of Yttria-Stabilized Zirconia (Y-TZP)

- 3 The Role of a Premier European Supplier

- 4 Navigating European Market Compliance (RoHS and REACH)

- 5 Manufacturing: From Powder to Sub-Micron Precision

-

6

Key Ferrule Specifications and Standards

- 6.1 The Language of Precision

- 6.2 Ferrule Outer Diameter (OD): 2.5 mm

- 6.3 Ferrule Outer Diameter (OD): 1.25 mm

- 6.4 Inner Diameter (Bore) Tolerance

- 6.5 Understanding Bore Concentricity

- 6.6 The Impact of Eccentricity on Loss

- 6.7 End-Face Geometry: Physical Contact (PC)

- 6.8 End-Face Geometry: Ultra Physical Contact (UPC)

- 6.9 End-Face Geometry: Angled Physical Contact (APC)

- 6.10 Telcordia Standards and Performance Grades

- 7 Quality Assurance: The Supplier's Guarantee

- 8 The Global Context of Zirconia Ferrule Sourcing

- 9 How to Evaluate a Zirconia Ceramic Ferrule Supplier

- 10 Conclusion

English

English 中文

中文