Inside the World of Zirconia Ceramic Machining

Zirconia ceramic machining is gaining attention in industries that demand strength, precision, and durability. From medical tools to aerospace parts, this material is proving its value. But what makes zirconia ceramics so special? And why is machining them such a challenge?

In this article, we'll explore how this tough material is being shaped with high accuracy. We'll look at the tools, methods, and breakthroughs that make it possible. There's more to it than just cutting hard surfaces - something few people talk about. Stay with us to uncover what really goes on behind the scenes.

Why Zirconia Ceramic Machining Matters Today

The Rise of Advanced Ceramics in High-Tech Industries

In today's fast-moving industries, traditional materials like metal and plastic often fall short. High-performance applications now demand more strength, durability, and resistance to extreme environments. That's why advanced ceramics are rising fast. Among them, zirconia stands out.

What Sets Zirconia Apart in the World of Machining

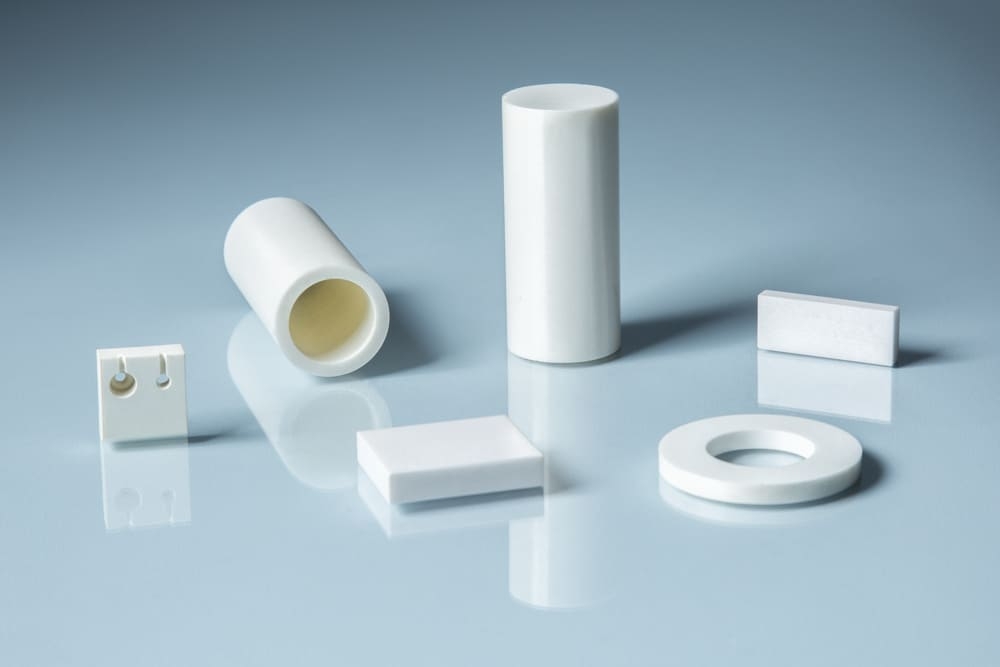

Zirconia is known for its toughness, stability, and long service life. Unlike other ceramics, it can handle pressure and friction without cracking. As a result, zirconia ceramic machining has become a key focus in industries like aerospace, electronics, and medical devices.

The Challenges and Opportunities in Zirconia Ceramic Machining

Machining zirconia ceramics is not easy. The material is hard and brittle, requiring advanced equipment and skilled techniques. But once done right, the results are impressive - parts with tight tolerances, high reliability, and exceptional durability. In the sections ahead, we'll explore what makes zirconia so special, and how it's changing modern manufacturing.

Unpacking Zirconia Ceramic: Material Properties That Redefine Performance

Exceptional Strength and Fracture Toughness

Zirconia ceramics offer one of the highest strength levels among advanced ceramics. They resist cracking under heavy load or impact, which makes them perfect for structural parts. This is one key reason why zirconia ceramic machining is now widely adopted for high-stress environments.

Thermal Stability and Corrosion Resistance

Zirconia holds up well in high temperatures. It doesn't melt or deform easily. It also resists corrosion from chemicals and gases. This is critical for applications in chemical plants, semiconductor processing, and automotive exhaust systems.

Electrical Insulation and Non-Magnetic Nature

Unlike metals, zirconia does not conduct electricity. This makes it ideal for electronic components and high-voltage systems. Also, zirconia is non-magnetic, allowing it to work in magnetic-sensitive environments, such as MRI machines or specialized sensors.

UPCERA's Strength in Zirconia Ceramic Machining

Precision That Begins with Material Control

At UPCERA, our zirconia ceramic machining process begins long before the first cut. We start with high-purity zirconium dioxide powders, selected and refined under strict standards. This gives us full control over the material's consistency, grain size, and performance. Stable raw material quality is the foundation for machining precision.

By managing the entire supply chain - from raw material development to final product - we ensure every ceramic part meets the exact requirements of our customers. Whether for aerospace components or dental tools, our machining starts with the right ceramic formulation.

CNC and Diamond Tooling for Extreme Precision

Zirconia is a very hard material. To shape it accurately, we use high-speed CNC machines and advanced diamond tooling. Our team operates specialized equipment designed for ceramics, not metals or plastics. This allows us to achieve ultra-fine tolerances, tight concentricity, and smooth surface finishes.

Surface roughness can reach Ra0.02–Ra0.2, and tolerances are kept within ±0.002 mm. Whether the project needs thin walls, micro-holes, or custom curved forms, our zirconia ceramic machining process delivers consistent quality.

Flexible Production for Custom and High-Volume Orders

We support both small-batch custom machining and large-volume manufacturing. For customized designs, we offer technical support from our R&D team, helping customers adjust specifications based on performance needs. For mass production, our high-efficiency process ensures fast lead times without sacrificing precision. Every piece we deliver is the result of careful machining, testing, and quality control.

Manufacturing Excellence: Inside Zirconia Ceramic Machining Techniques

From Raw Zirconia to Precision Parts

Zirconia starts as a fine powder. This powder is pressed and sintered into solid ceramic blocks. The blocks are then ready for machining. At this stage, zirconia ceramic machining transforms raw material into highly accurate parts. Every step is controlled to ensure performance and reliability.

Complex Geometry and Custom Design Capabilities

Modern zirconia ceramic machining allows us to create complex shapes. From thin walls to tight curves, we meet demanding design needs. We support custom drawings, small batches, and large-scale orders. No matter the challenge, precision always comes first.

Reliable Supply, Trusted by Global Clients

Quality Assurance from Start to Finish

We follow a strict inspection system throughout the zirconia ceramic machining process. From raw block preparation to final polishing, every step is monitored for consistency and accuracy. Our team uses 3D measurement tools, digital microscopes, and thermal testing equipment to ensure each part meets spec.

Used Across High-Stakes Industries

Our machined zirconia ceramic parts are used by global customers in industries where failure is not an option - such as optical communications, medical devices, semiconductor tools, and energy systems. UPCERA is proud to be a long-term supplier to many international clients who rely on us for both innovation and reliability.

How Zirconia Ceramic Structural Parts Are Used Today

Robotics, Automation, and Semiconductor Fabrication

Zirconia structural parts are widely used in automation systems. They serve as guide rails, bearings, and structural supports. In semiconductor tools, zirconia provides chemical resistance and dimensional stability. Thanks to zirconia ceramic machining, these parts meet the high precision required in cleanrooms and fabs.

Medical Devices, Dental Implants, and Biocompatible Tools

Zirconia is biocompatible. It is used in surgical tools, dental implants, and medical instruments. It does not react with body fluids or tissues. Its strength and polish also help prevent bacterial growth. These features make zirconia a reliable choice in the health industry.

Energy, Automotive, and Environmental Systems

In energy systems, zirconia resists heat, pressure, and corrosion. It is used in fuel cells, insulators, and catalytic supports. In vehicles, it helps with exhaust systems, sensors, and valves. These applications rely on the high durability made possible by advanced zirconia ceramic machining.

Zirconia Ceramics and the Future of Precision Engineering

R&D Trends and New Ceramic Material Breakthroughs

The field of ceramics is still evolving. Researchers are exploring new ways to improve strength, reduce weight, and lower costs. Advanced zirconia ceramic machining will play a key role in turning new materials into usable parts for next-generation technologies.

UPCERA's Vision for Global Ceramic Solutions

At UPCERA, we believe in continuous improvement. We invest in smarter production, better materials, and faster service. We aim to be more than a supplier - we are a trusted partner. Our goal is to help customers overcome technical limits and succeed in their markets.

Conclusion: How Zirconia Will Power Next-Gen Technologies

Zirconia ceramics are ready for the future. From clean energy to smart electronics, they offer performance that metal and plastic cannot match. With advanced zirconia ceramic machining, we can shape tomorrow's components - one micron at a time.

In This Article

- 1 Why Zirconia Ceramic Machining Matters Today

- 2 Unpacking Zirconia Ceramic: Material Properties That Redefine Performance

- 3 UPCERA's Strength in Zirconia Ceramic Machining

- 4 Manufacturing Excellence: Inside Zirconia Ceramic Machining Techniques

- 5 Reliable Supply, Trusted by Global Clients

- 6 How Zirconia Ceramic Structural Parts Are Used Today

- 7 Zirconia Ceramics and the Future of Precision Engineering

English

English 中文

中文