How Zirconia Ceramic Welding Dowel Pin Outperforms Metal Pins

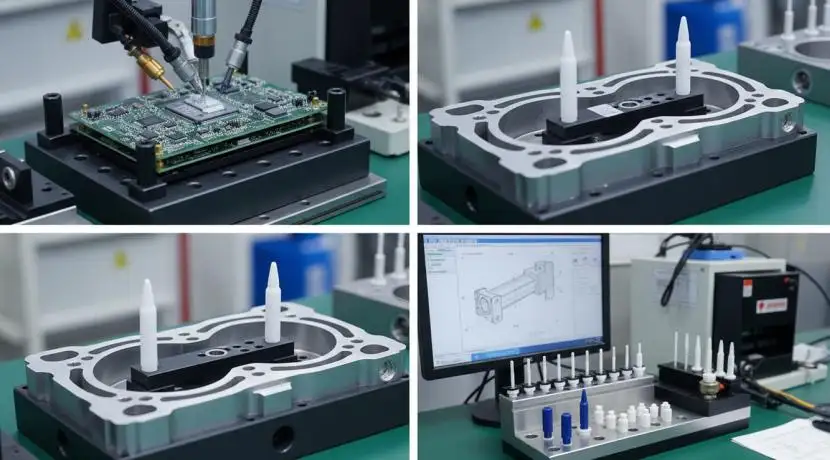

The Zirconia Ceramic Welding Dowel Pin looks like an ordinary locating pin, but it does a very special job in welding and precision fixtures. It is a high-strength ceramic pin used to position and support parts during welding and assembly. Unlike traditional metal pins, it resists wear, high temperature, and corrosion. It is also non-magnetic and electrically insulating. Many manufacturers still rely on metal pins every day. Yet once they switch to zirconia, they often see unexpected changes in quality, stability, and cost - sometimes in ways that surprise their engineers.

Why Metal Pins are Holding Your Process Back

For many manufacturers, metal dowel pins are still the default choice. They're widely available, inexpensive to buy, and familiar to every toolmaker. But once they go into a real welding or assembly line, the picture changes:

•High welding temperatures and thermal cycling

•Flux, fumes, and cleaning chemicals

•Repeated clamping, positioning, and removal

•Long production runs with minimal downtime

Over time, metal pins start to tell the story. Surfaces wear and pick up burrs, diameters drift, pins bend slightly or become magnetized, and corrosion appears in humid or chemically aggressive environments. None of this happens overnight, but the effects add up:

•Fixtures no longer locate parts as precisely as they did on day one

•Operators spend more time tweaking offsets and re-aligning parts

•Scrap creeps up, cycle times get longer, and inspection finds more defects

When we help customers trace these problems back to their source, we often land on the same root cause: the locating function is being done by a component that was never designed to stay dimensionally stable under such harsh conditions.

How a Zirconia Ceramic Welding Dowel Pin Behaves Differently

A Zirconia Ceramic Welding Dowel Pin responds to the same environment in a completely different way. Zirconia engineering ceramic has a set of properties that make it ideal for precision locating in demanding welding and assembly processes:

•Extreme wear resistance - The working surface keeps its geometry through thousands of cycles.

•Corrosion resistance - Zirconia does not rust or oxidize, even with aggressive chemicals or high humidity.

•High temperature stability - The material maintains its structure and dimensions at elevated temperatures.

•Electrical insulation and non-magnetic behavior - It will not conduct stray current or disturb magnetic fields.

In many UPCERA designs, the ceramic does the critical locating work, while a metal shank or base provides familiar mounting into an existing fixture. This hybrid structure makes it easy to drop a Zirconia Ceramic Welding Dowel Pin into a tool that was originally designed around metal, minimizing redesign work while immediately improving performance.

- Engineered for Predictable, Long-term Accuracy

For engineers, it's not just about strength on paper - it's about how the pin behaves after months or years in production. Each UPCERA Zirconia Ceramic Welding Dowel Pin is manufactured with that long-term predictability in mind.

Typical capabilities include:

•Lengths up to around 300 mm, suitable for deep fixtures and complex jigs

•Outer diameters up to about 150 mm

•Surface roughness in the range of Ra 0.02 - 0.2, ensuring smooth guidance and clean contact

•Minimum wall thickness down to roughly 0.1 mm, enabling compact, lightweight designs

•Roundness and concentricity on the order of 0.002 mm, helping fixtures repeat position with high consistency

These figures are not just catalog data. They translate directly into process results:

•The locating feature stays within microns of its intended shape

•Welds and assembly points remain where your CAD and programs expect them to be

•You don't need to constantly "chase" wear by adjusting reference points in the controller

Thermal and chemical stability are just as important. While metal pins may soften, oxidize, or react with flux and fumes, a Zirconia Ceramic Welding Dowel Pin stays dimensionally stable across repeated heat cycles. In other words, fewer "what happened over the weekend?" moments, and fewer quality shifts that appear right after a tooling clean or minor process change.

- From Technical Advantage to Financial Gain

On a real production line, this shows up as:

•Fixture accuracy that stays within spec for longer

•Fewer defects traced back to locating pins

•Extended maintenance intervals and fewer pin swaps

•A lower overall cost per welded or assembled component

While a Zirconia Ceramic Welding Dowel Pin is more expensive than a basic metal pin, it changes the cost structure of the fixture. Less scrap, less downtime, and fewer adjustments quickly offset the purchase price and become visible savings in your production reports.

- Where Zirconia Ceramic Welding Dowel Pin is a Smart Upgrade

UPCERA's ceramic pins are used wherever alignment is critical and the environment is tough on metal:

•Precision welding jigs and fixtures

Keeping components in exact position during robotic or manual welding, even under repeated heating, clamping, and cleaning.

•Electronics and semiconductor tooling

Providing non-conductive, non-magnetic reference points for PCBs, wafers, and fine-pitch components, helping protect sensitive circuits from stray fields and currents.

•Medical device manufacturing

Offering clean, inert locating elements inside fixtures used for surgical instruments, implants, and diagnostic equipment, where contamination and corrosion are not acceptable.

•Automotive and aerospace production

Supporting jigs and fixtures that must hold tight tolerances through temperature cycles, long runs, and frequent changeovers.

•Optical, laser, and measurement systems

Maintaining position where even minor misalignment can degrade performance, accuracy, or calibration.

Many customers start with a simple test: they replace just a few critical metal pins in an existing fixture with UPCERA's Zirconia Ceramic Welding Dowel Pin and run normal production. After several months, they measure and inspect. The ceramic pins typically still look and measure close to new, while the remaining metal pins clearly show wear and drift. That side-by-side comparison often becomes the business case to standardize zirconia across more fixtures.

How UPCERA Supports Your Transition

UPCERA is more than a catalog of standard zirconia parts. Our engineering team works with you to specify the right Zirconia Ceramic Welding Dowel Pin for your process. Together, we look at:

•Operating temperature, fumes, and cleaning methods

•Required positioning accuracy and repeatability

•Available space and mounting type in the current fixture

•Whether a full ceramic pin or a ceramic–metal hybrid design makes more sense

From there, we recommend a configuration that fits your existing tooling or supports a new fixture concept. The goal is straightforward: improve process stability and quality without adding unnecessary complexity or cost.

Ready to Rethink Your Locating Strategy?

If your team is fighting drifting tolerances, frequent pin replacement, or mysterious variation in weld quality, the problem may not be your robots or programs - it may be the pins they rely on.

Reach out to UPCERA's engineering team to discuss a Zirconia Ceramic Welding Dowel Pin solution tailored to your line. A short technical conversation can turn a small, often overlooked component into a reliable backbone for long-term, high-quality production.

English

English 中文

中文