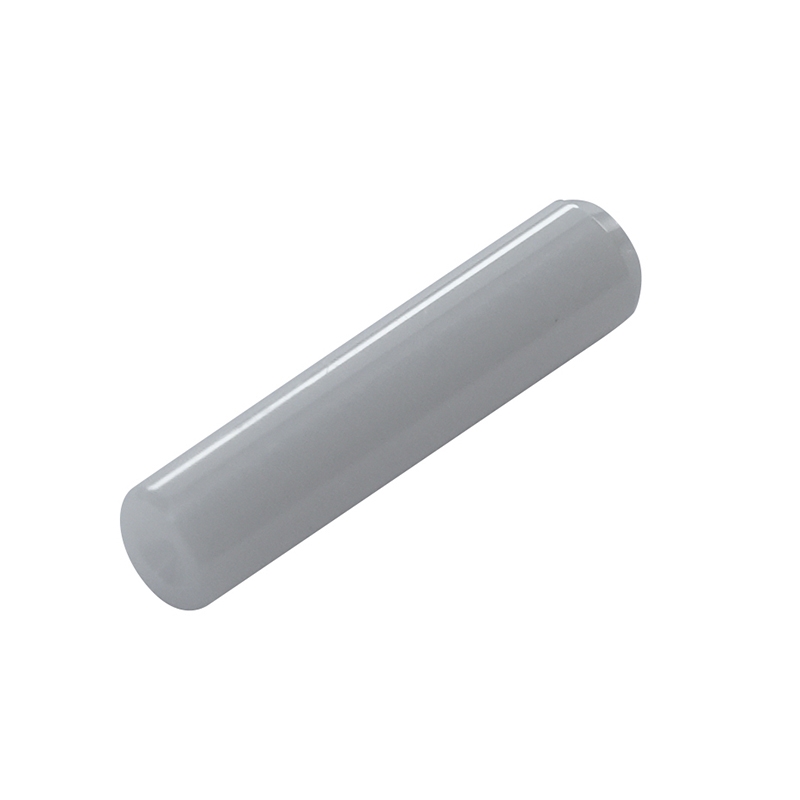

Zirconia Structural Components for Extreme Environments

Zirconia Structural Components keep machines alive when heat, friction, and corrosive media attack. They resist wear. They stay stable under sudden temperature shifts. They insulate where metals conduct. In labs and on production lines, they hold tight tolerances longer. Downtime drops. Quality holds. Yet many teams still rely on parts that fail early. Why? What changes when zirconia replaces metal or polymer? In the next section, we reveal the hidden failure modes, the real cost drivers, and the design details that decide success - or a costly rerun.

Why Zirconia Structural Components Outlast Metals In Harsh Conditions

Most performance failures cluster around three pain points: thermal shock, abrasive wear, and chemical attack. Metals can soften, gall, or corrode; polymers can creep, swell, or outgas. Zirconia (ZrO₂) offers a different path. It combines high fracture toughness with excellent wear resistance, stable behavior under rapid temperature swings, and strong chemical inertness. That balance yields predictable performance across wide operating windows and long maintenance intervals.

In dynamic assemblies - bearings, guides, and sliding interfaces - Zirconia Structural Components hold their geometry even when friction and vibration are high. Dimensional accuracy remains intact through thermal cycling, so your tolerances stay true. Bearings do not seize from drift, seals keep alignment, and metrology tools sustain calibration. Another advantage is electrical: zirconia is an excellent insulator and is non-magnetic. It blocks stray currents and avoids magnetic interference in high-voltage modules or sensor-dense systems, improving both safety and signal fidelity.

Engineers value zirconia because it reduces the "unknowns" that creep into complex machines over time. Maintenance teams value it because changeouts come less often and are more predictable. Operators value it because stable components raise OEE and reduce scrap. For sectors where a brief outage can cost more than the component itself - semiconductor, aerospace, energy, chemical processing - the math becomes compelling.

✅ Key Reliability Gains You Can Measure

• Fracture Toughness: Resists cracking under high loads, impact, and vibration.

• Wear Resistance: Maintains surface integrity in sliding or rotating pairs.

• Chemical And Thermal Stability: Performs in acids, alkalis, and hot gases without degrading.

• Electrical Insulation & Non-Magnetic: Safeguards electronics and magnetically sensitive equipment.

How UPCERA Tailors Zirconia To Your Use Case

UPCERA delivers factory-direct quality with application-driven engineering support. We begin with the physics of your system: load cases, duty cycle, temperature envelope, mating materials, and cleanliness requirements. From there, we translate those inputs into a zirconia grade and a manufacturable geometry that preserves critical features while minimizing risk in sintering and finishing. The aim is simple: consistent, repeatable parts that work on the floor - not just on paper.

Projects often stall where complex design meets producibility. Thin walls can distort. Grain growth can weaken edges. Stress concentrators can invite microcracks. UPCERA addresses these issues with controlled sintering profiles, stable fixturing, and precision machining sequences that protect tolerances and surfaces. The result is a part that passes qualification and keeps passing long after deployment.

✅ Design Inputs That Matter

• Operating Loads & Dynamics: Determines section thickness and fillet strategies.

• Thermal Profile: Guides allowance for thermal cycling and shock resistance.

• Media & Cleanliness: Influences material grade and surface finish.

• Mating Components: Drives fits, tolerances, and edge protection.

• Inspection Plan: Aligns drawing callouts with metrology methods from day one.

✅ Capabilities And Tolerances

UPCERA supports complex geometries while holding production-grade precision for Zirconia Structural Components:

• Length Range: ≤ 300 mm

• Outer Diameter: ≤ 150 mm

• Minimum Wall Thickness: 0.1 mm

• Surface Roughness: Ra 0.02 - 0.2

• Roundness: 0.002 mm

• Concentricity: 0.002 mm

• Straightness: 0.004 mm

• Perpendicularity: 0.005 mm

These numbers enable confident integration into tight assemblies - valve trains, sensor housings, wear plates, guides, insulating standoffs, and precision nozzles - without redesigning your stack-up. Just as important, our factory-direct model stabilizes lead times and ensures lot-to-lot repeatability from prototypes through volume delivery.

Where The ROI Shows Up In The Field

Return on investment comes from extended service life, fewer interventions, and better process stability. But it also shows up in places you might not expect: cleaner electrical signals, lower contamination risk, and more predictable calibration intervals. Below are common environments where Zirconia Structural Components demonstrate clear value:

• Aerospace & Defense: Structural inserts and wear interfaces that endure vibration, pressure, and temperature extremes without dimensional drift.

• Semiconductor Equipment: High-purity, dimensionally stable parts for wafer handling and chemical processing where contamination control is critical.

• Medical & Dental Systems: Biocompatible, durable components for tools and support structures that tolerate repeated sterilization.

• Robotics & Automation: Guides and plates that resist repetitive stress and abrasive slurries in high-duty cycles.

• Automotive & Energy: Heat- and wear-resistant housings, exhaust-adjacent parts, and insulating components for high-voltage systems.

The operational story is consistent: longer MTBF, fewer unplanned stops, and lower total cost of ownership. In procurement terms, you see fewer supplier changes, fewer incoming inspection holds, and far fewer line interruptions. In engineering terms, you get a robust, insulating, corrosion-resistant component that halts the slow drift of variance that undermines reliability programs.

Call To Action 0 Partner With UPCERA

If you are wrestling with thermal shock, corrosion, or wear, evaluate Zirconia Structural Components with a partner that understands both material science and production realities. Share your drawings and operating conditions with UPCERA for a rapid DFM review and a tailored quotation. We will help you convert critical metal or polymer parts to zirconia - without compromising tolerance, throughput, or budget.

English

English 中文

中文